While Our Competitors Use T-1 Type Steel, All of Superior Plow Blades Bits and Blades Bits and Blades Are Manufactured Using Hardox Wear Plate, a Proven Performer!

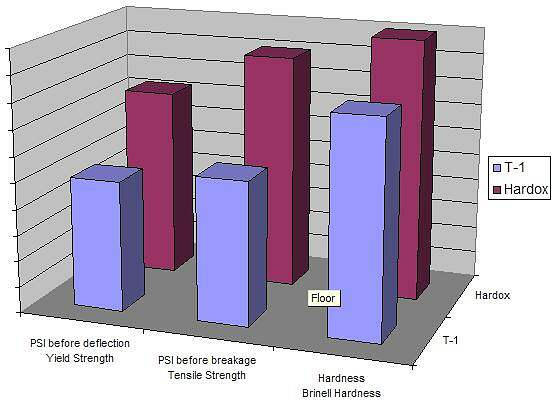

Steel Comparisons: HARDOX versus T-1

Yield Strength

Hardox - 145,000 PSI before deflection

T-1 - 100,000 PSI before deflection

Tensile Strength

Hardox - 180,000+ PSI before breakage

T-1 - 110,130 PSI before breakage

Brinell Hardness

Hardox - 400 hardness

T-1 - 320-340 hardness

Hardox Wear Plate is the leading brand name all over the world. Known for wear resistance, quality, and consistency. A Swedish manufactured high alloy plate.

It offers excellent sliding and abrasive resistance as well as memory (the ability to flex and return to it's original shape).

3 Chute Options for Plowing Multiple Products

- The standard and least expensive option is the extra-deep chute.

- The diameter and number of products, decides the depth required.

- Remember when ordering cover depths for multiple product’s, we need to know if the cover depth is for the top product or the bottom product.

Extra deep chute

Products stack on top of each other inside chute

Bolt-in divided chute

Can accommodate individual channels for each product inside one overall chute. The chute pictured has two channels and one divider. The channels can be designated for different sizes or the same, depending on products being installed. Extra inside depth must be calculated for each diameter chute and also the thickness of the divider piece.

Piggy Back Chutes

Allows blade to be used with only one chute or multiple chutes stacked. Each chute will come with its own gate and if ordered ribbon and or wire tubes. Up to two extra piggy-back chutes can be used on one blade making a total of 3 chutes.

How our products are stamped

Chuted blades are stamped with inside chute width, cover depth of product and radius.

They also contain a 4 digit stamp which correlates to our shop work orders.

If you are re-ordering a blade and you have this information it can help you and us. Also if you aren’t sure of blades cover depth, it is already recorded on the blade for you.

The numbers are found on the wing-nut side of the blade and stamped into the chute.

Reamers have date of production and hole diameter, welded on.

Pull Blade vs Chuted Blade

Pull Blade – Product is attached to 2 ears (the ears/tabs have holes drilled in them- top left side of blade), and then pulled through a trench that is made by the vibrating plow blade. The bullet that the ears are attached to is the same diameter as product being pulled or a little bit bigger.

A lost motion bullet can be attached to the ears also. If a 3” lost motion is attached to a 2 ½” welded-in bullet, a larger product can be pulled in, allowing a blade to do double duty. Also a lost motion bullet can keep the product being pulled into the ground from vibrating so much, as the shaker box works the blade into the ground.

Chuted Blade – Product is fed through a chute, entering from the top right side of the above blade and existing from the top left side of blade.

What is a combo blade?

Combo blades are a combination chuted and pull blade in one blade. The chute is slid up. This allows you to pull in one product and plow in another right above it.

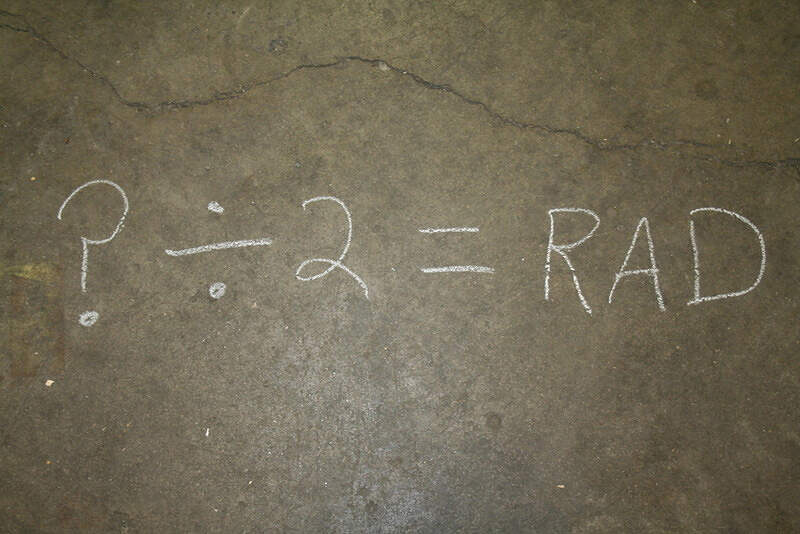

How to measure an existing blade to find out what the radius of the chute is

Step #1 – Remove existing gate/guide from chuted blade.

Step #2 – Trace the curve of the gate/guide.

Step #3 – Flip gate/guide over and trace again to get a half circle.

Step #4 – Measure distance from top of circle to bottom for the diameter.

Step #5 – Take the diameter anddivide by 2 and this equals the radius of the curve of the blade.

Step #6 – Example: Diameter is 9”. Divide 9” by 2 = 4.5”

What is a combo blade?

Combo blades are a combination chuted and pull blade in one blade. The chute is slid up. This allows you to pull in one product and plow in another right above it.

Will Do Stocking Orders!

Save freight by placing stocking orders, for blades that are purchased on a regular basis.